How to use pendant stations at your factory

In industries, it is required to move bulky and

heavy loads, either on the floor or through aisles, and it takes time and can

also cause injuries. In such cases, it is better to use overhead crane, which

can easily handle and move heavy loads. Movement of these cranes is done with

the help of pendant stations. A series of simple switches used to control

larger electrical loads through different means is called Hoist pendant station or simply pendant station. These loads may be either hoists or

cranes, but it can be used to control conveyer belt systems and production line

equipment. In pendant stations, there are low power pilot duty switches

connected to relays, programmable logic controllers or automation circuitry to

control larger loads. Generally, pendant stations are used to move and control

large cranes and hoists. Apart from this, they can be used as remote control

for industrial machines.

Electromechanical devices, which are used to

regulate appliances and industrial machinery are called limit switch. These

switches can also be used to control cranes, as these limit the crane from

lifting loads above rated capacity and are also called crane limit switches.

In few cases, there are multiple switches, which are associated with crane

operation. First switch gives the signal that the end of safe travel limit is

being approached and therefore crane motion is slowed and the second switch

indicates that it is end of safe travel distance is reached and stops the crane

motion. If it is required to control the hoist motion, then there required more

limit switches, and these switches provide set points for safety and

reliability.

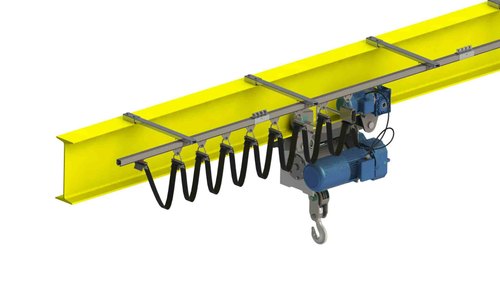

One of the challenges in crane technology is to

manage cables with reliability. Festoon systems are used to support

conductor cables and hoses which deliver power and control to equipment which

are mobile, in an efficient maintenance free and safe method. These are cable

carriers, which guide cables in their tracks and protect it against humidity

and dust. In festoon systems, cables hang loose while moving, these cables can

swing and get caught in crane structure, during bad weather, and this may

require repairs, which is costly. Festoons are used for ship to shore cranes,

and there are high winds, heavy rain and other factors, which may cause damage

to festoon systems. To avoid these maintenance costs, alternative

electrification system is used by crane manufacturers, it is called energy

chain.

No comments:

Post a Comment